Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

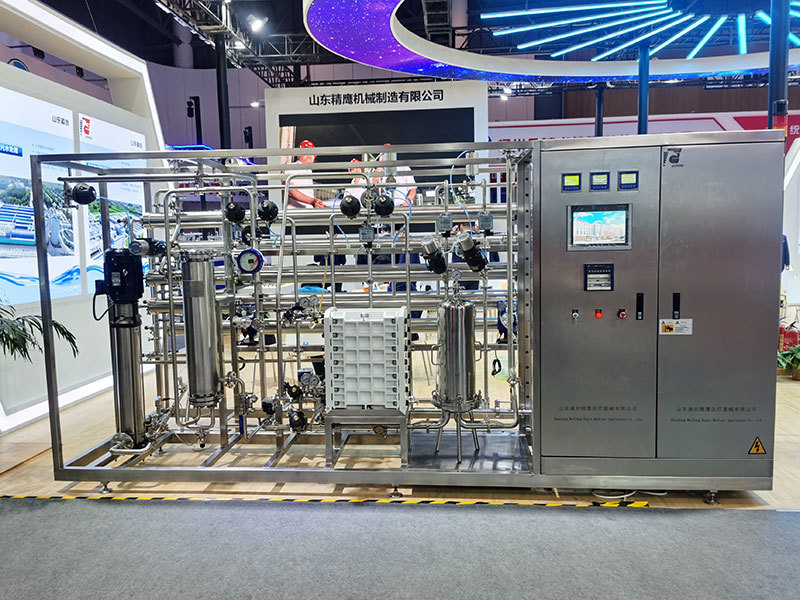

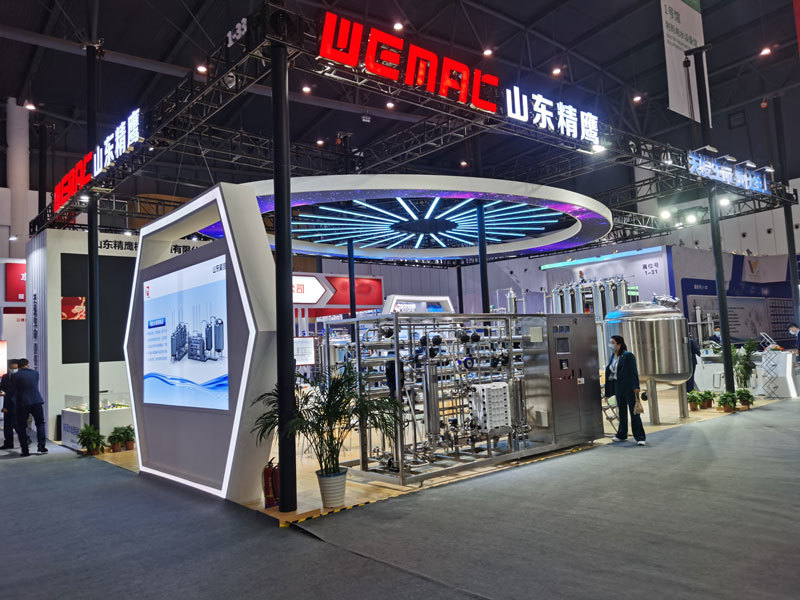

Stainless Steel Purified Pharmaceutical Ro Water Treatment Plant System

According to the raw water quality report and the output water quality requirement of the customer, WEMAC can provide you a full range of configuration about purified water equipment. Depends on different configuration, the water quality can meet the requirement of CP2010. USP34, EP7 to the purified water or ultra purified water

According to the raw water quality report and the output water quality requirement of the customer, WEMAC can provide you a full range of configuration about purified water equipment. Depends on different configuration, the water quality can meet the requirement of CP2010. USP34, EP7 to the purified water or ultra purified water。

WEMAC customized optimization design according to the raw water quality report,effluent quality requirements and the actual needs of customers, and customer can also choose the standardized design from WEMAC. The output water quality can meet the requirements of Chinese Pharmacopoeia(CP2020), United States Pharmacopoeia (USP43) and European Pharmacopoeia (EP10) for purified water or high purity water according to different system configurations.

WEMAC customized optimization design according to the raw water quality report,effluent quality requirements and the actual needs of customers, and customer can also choose the standardized design from WEMAC. The output water quality can meet the requirements of Chinese Pharmacopoeia(CP2020), United States Pharmacopoeia (USP43) and European Pharmacopoeia (EP10) for purified water or high purity water according to different system configurations.

Water system for pharmaceutical

WEMAC customized optimization design according to the raw water quality report,effluent quality requirements and the actual needs of customers, and customer can also choose the standardized design from WEMAC. The output water quality can meet the requirements of Chinese Pharmacopoeia(CP2020), United States Pharmacopoeia (USP43) and European Pharmacopoeia (EP10) for purified water or high purity water according to different system configurations.

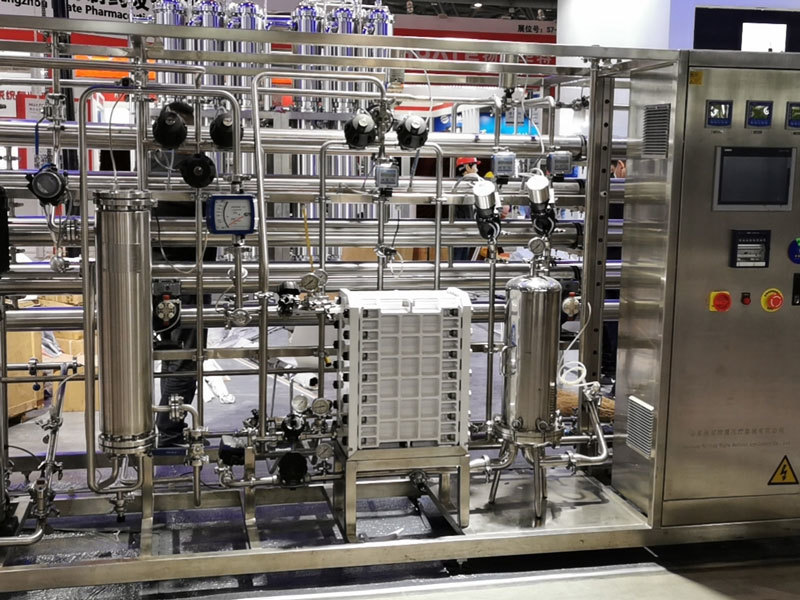

Reverse osmosis mainly uses the permeation principle of a semi-permeable membrane to apply a pressure to it in a certain way. The force opposite to the natural permeation direction makes the water in the concentrated solution penetrate into the dilute solution. This method is called reverse osmosis. The device composed of reverse osmosis elements is a reverse osmosis device.

Pharmaceutical water treatment system

The first step in pharmaceutical water treatment equipment is the preparation of purified water system.Pharmaceutical purified water can be prepared by suitable methods such as reverse osmosis. Reverse osmosis technology is currently a relatively mature and efficient membrane separation technology. Its application in purified water equipment systems can achieve stable water production and meet the technical indicators required by the pharmaceutical industry.

The Water treatment machinery is composed of storage tanks, conveying pumps, conveying circulation pipelines, water points, monitoring and control systems. Temperature and other needs, and maintain water quality in line with pharmacopoeia requirements.

The water treatment process of water system inpharma mainly adopts reverse osmosis technology and is used in conjunction with pretreatment devices, and must be sterilized and sterilized before the water point, and ensure that the produced qualified water can be stably and safely transported to the water point. Reverse osmosis technology is a widely used desalination treatment technology, which can greatly reduce the load of ion resin, and the amount of resin regeneration agent is only 10% of the traditional ion exchange resin process, which not only saves operating costs, but also is relatively friendly to the environment.

Water purifying equipment is a kind of raw material water commonly used in the pharmaceutical industry and participates in the entire production process engineering.

Water purification systems industrial

Pipelines and delivery pumps for transporting purified water and water for injection should be regularly cleaned, disinfected and sterilized, and can only be put into use after passing the verification.

PW water system strictly purifies the raw water to make it meet the water quality standards for pharmaceutical production, and the process from water production to delivery to the water point is easily subject to secondary pollution, which will affect the final water quality effect.

In the process design of pharmaceutical water purification machine, the appropriate process flow is selected according to the user's raw water report and product water standards to ensure that the final product water quality meets the standards.

For pharmaceutical water purification equipment systems, in addition to paying attention to equipment selection and equipment prices, people in the pharmaceutical industry will also attach great importance to the operation and maintenance of equipment after investment.

The use of purified water is inseparable from the raw water report. Generally, pharmaceutical companies use municipal tap water as raw water. If the company does not sample the raw water and cannot provide a tap water quality report, you can contact the local tap water supply company and ask the tap water supply company to produce a water quality report.