Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

Reverse osmosis equipment has single-stage RO and double-stage RO, which can be selected according to raw water quality and product water requirements. The difference between single-stage RO and double-stage RO in reverse osmosis equipment is that the water treated by double-stage RO is more "pure" than the water from single-stage RO, which meets the higher water demand of enterprises.

Reverse osmosis water purification machine

The operation of reverse osmosis purified water equipment is mainly divided into several parts: normal operation, operation monitoring, automatic flushing, and so on.

Water system in pharma industry

The Water system in pharma industry adopts the most advanced fully automatic two-stage RO reverse osmosis purified water treatment technology, and is used in conjunction with the pre-treatment. It uses the principle of reverse osmosis to effectively remove various salts and impurities in the water, and uses EDI electrodeionization equipment to further Improve water quality; the system has the advantages of advanced technology, stable water quality, simple operation, low operating cost, green environmental protection, no pollution, and convenient maintenance.

Pharmaceutical Water generation systems

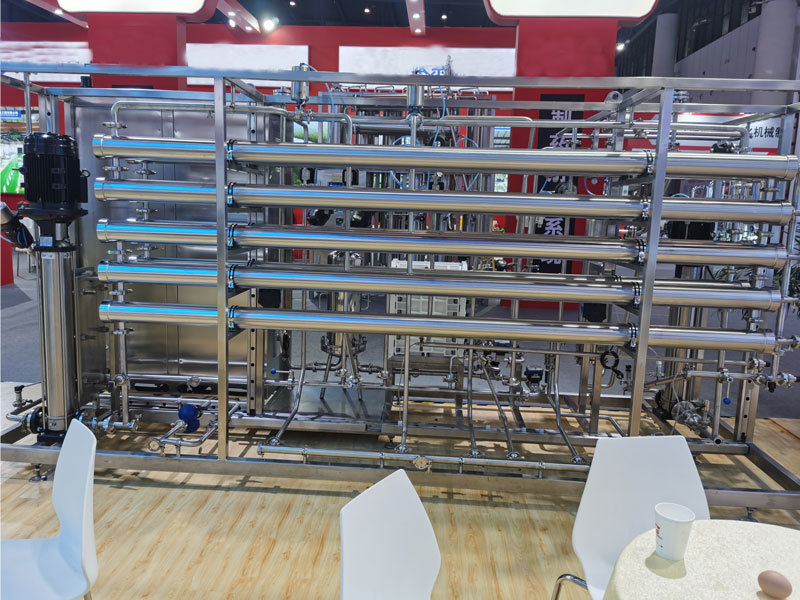

1. High configuration of Pharmaceutical Water generation systems High-grade stainless steel water tank→raw water pressure pump→automatic multi-media filter→automatic activated carbon filter→(automatic water softener)→precision filter→first-stage reverse osmosis→secondary reverse osmosis→sterile purified water tank→pure water pump→ozone Sterilization system → ultraviolet sterilizer → microporous filter → water point.

Purified water system in pharmaceutical industry

The medical Purified water system in pharmaceutical industry is made of stainless steel and must be equipped with a sterilization device before the point of use. Using the latest technologies such as reverse osmosis and EDI, a complete set of high-purity water treatment processes are designed in a targeted manner to meet the water requirements for the production of purified water in pharmaceutical factories and hospitals, and the production of large-scale infusions.

Purified water system 316L 304

In the Wholesale Purified water system 316L 304 cost purified water equipment, generally the device before the secondary RO water production is made of 304 stainless steel, and the device after the secondary RO water production can be made of 304 or 316L stainless steel.

Purified water plant in pharmaceutical industry

The materials used in the pipes of the Purified water plant in pharmaceutical industry should be non-toxic and corrosion-resistant. Commonly used materials are 304 stainless steel and 316L.

The core technological feature of the purified water plant is that it uses the water source that meets the drinking water standard as the raw water, passes through the raw water pressurized pump, and passes through the pretreatment unit composed of multi-media filter, activated carbon filter and softener for primary purification. , and then the water flows through the security filter. Remove particles larger than 5 microns, so that the pretreated effluent can reach the influent conditions of the subsequent system.

Purified water generation system

The commissioning of the Purified water generation system includes Factory Acceptance Test (FAT) and Site Acceptance Test (SAT). Commissioning requires well-planned, documented and project management and is a method for start-up and handover of equipment systems to the end user.

Purified water distribution system

The purified water storage and distribution system is composed of storage tanks, conveying pumps, conveying circulation pipelines, water points, monitoring and control systems. Temperature and other needs, and maintain water quality in line with pharmacopoeia requirements.

Pharmaceutical equipment includes API equipment and machinery; preparation machinery; pharmaceutical crushing machinery; decoction piece machinery; pharmaceutical water equipment; pharmaceutical packaging machinery; drug testing equipment; other pharmaceutical machinery and equipment (pharmaceutical auxiliary equipment).

A complete set of Pure water production line, including pretreatment system, secondary RO system, EDI system, storage system, distribution system, disinfection system, metering pump dosing, electrical, control and other auxiliary systems, effectively remove various salts in water and impurities, so that the water quality of the product meets the water quality requirements of your company's production process.

The purified water used in the pharmaceutical pure water making machine industry should be suitable for its purpose. The safety of the process and technology of pure water making machine must meet the requirements of relevant regulations and standards, such as GMP, FDA and other certification requirements, which is also the basic condition to ensure the stability and reliability of the system.

Pure water generation system is a common water supply system in the pharmaceutical industry, which can meet the high water quality standards of the pharmaceutical water production line.

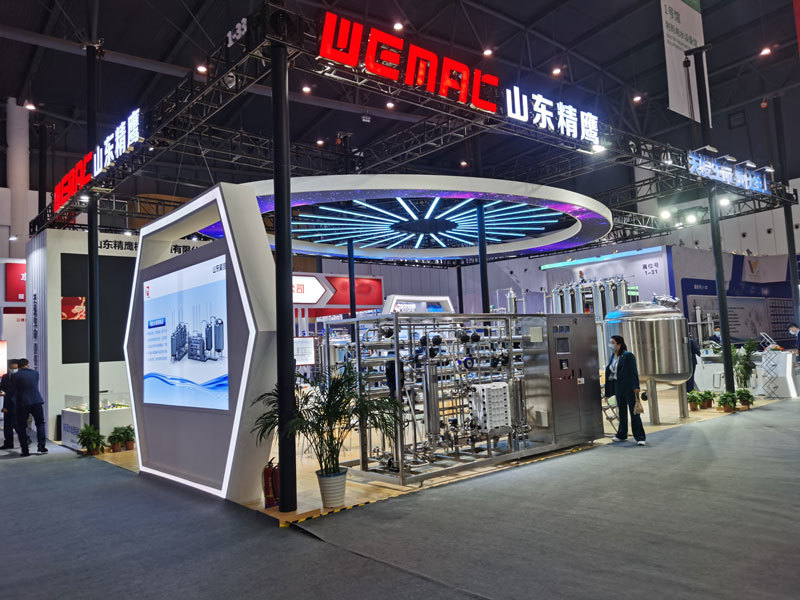

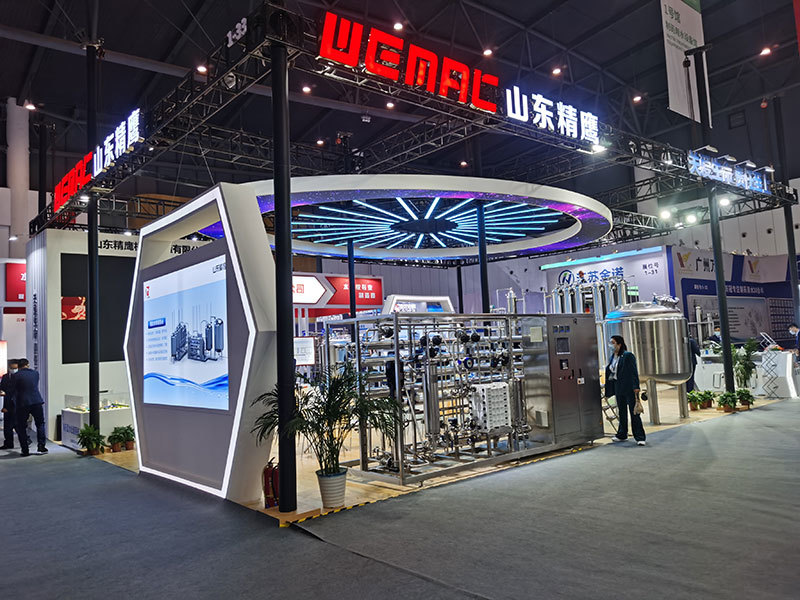

WEMAC provides customers with design, manufacturing,installation and verification support for injection water system and liquid preparation system.