Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

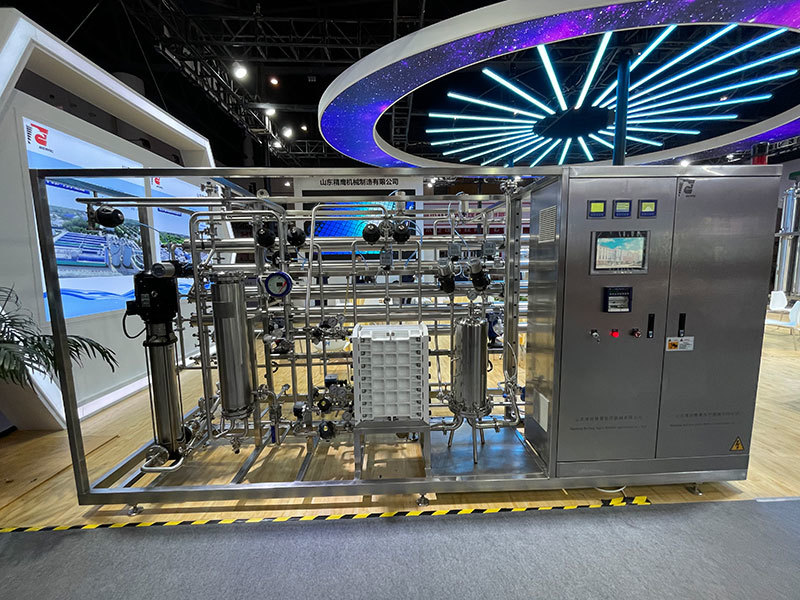

RO2

Reverse osmosis mainly uses the permeation principle of a semi-permeable membrane to apply a pressure to it in a certain way. The force opposite to the natural permeation direction makes the water in the concentrated solution penetrate into the dilute solution. This method is called reverse osmosis. The device composed of reverse osmosis elements is a reverse osmosis device.

Keywords:

category:

Details description

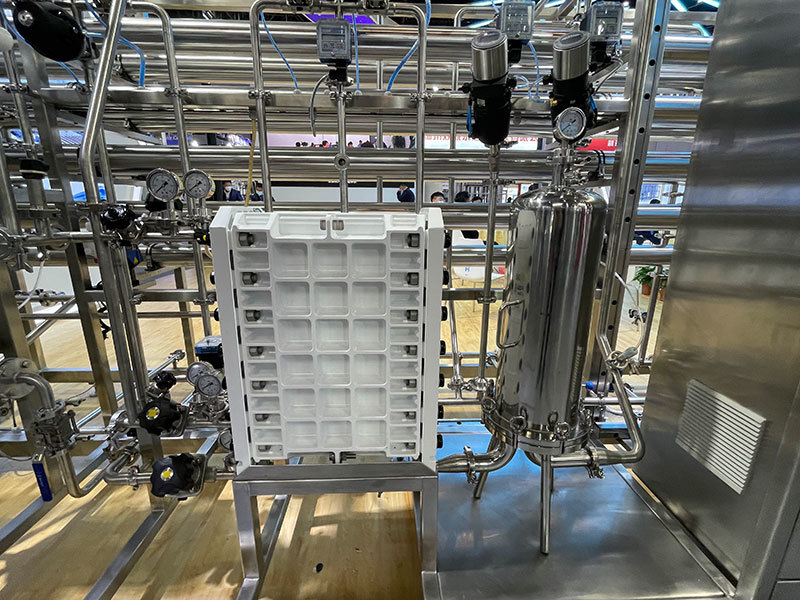

Reverse osmosis mainly uses the permeation principle of a semi-permeable membrane to apply a pressure to it in a certain way. The force opposite to the natural permeation direction makes the water in the concentrated solution penetrate into the dilute solution. This method is called reverse osmosis. The device composed of reverse osmosis elements is a reverse osmosis device. Applied to pure water in electronics, medicine, food and other industries; purification and preparation of water for textiles and chemical industries; purification and preparation of water for food and beverage and brewing process water; concentration and recovery of useful substances in aqueous solutions in industrial production; power plants, etc. Pre-desalination treatment of make-up water for high-pressure boilers of enterprises; desalination of brackish water and seawater; as a first-level desalination equipment for high-purity water production.

Process characteristics of pure water prepared by two-stage reverse osmosis:

Suitable for areas with low salt content in raw water

Low total carbon content (organic matter) in water production

Pollution-free emissions

The structure is relatively simple

Purified water preparation process:

Pre-treatment + RO1 + RO2

Optional disinfection methods: activated carbon pasteurization, CIP cleaning system, distribution system ozone sterilization, distribution system pasteurization, distribution system pure steam sterilization.

Remarks: The water system system is customized according to user requirements (URS)

Can choose 304 or 316L material, and use professional equipment and equipment to strictly inspect the quality;

Modular 3D design, construction according to drawings;

The pipeline connection method uses welding first, followed by clamp connection to control the growth of microorganisms;

Using orbital automatic welding machine, 20% endoscope inspection after welding, 100% endoscope inspection after manual welding;

| Name | Description | |||||

| Pre-treatment system | Pretreatment process contains traditional processes, such as Feed water storage tank,Heat exchanger heating device,Mechanical filtrater, activated carbon filtrater, softener,Precision Filter, dosing device, as well as ultra-filtration, residual chlorine removal UV, micro-filtration, etc. | |||||

| RO2 system | Based on demands of raw water quality conditions and terminal water,RO2 can be used as terminal processing of PW generation system. If alkalinity of raw water is on the high side, degassing device can be chosen. The water quality conforms to requirements of Chinese pharmacopoeia, European pharmacopoeia and United States pharmacopoeia. |

|||||

| RO1+EDI system | Based on demands of raw water quality conditions and terminal water, RO1 +EDI can be used as terminal processing of PW generation system. Quality of water produced by RO1 + EDI is stable, only slightly affected by fluctuation of raw water quality. The water quality conforms to requirements of Chinese pharmacopoeia, European pharmacopoeia and United States pharmacopoeia. |

|||||

| RO2+EDI system | Adopting RO2+EDI system as terminal processing of PW generation system, produced water will only be slightly affected by fluctuation of raw water quality. Quality of produced water is stable and highly above requirements of Pharmacopoeia. | |||||

| Residual chlorine removal UV system | Using residual chlorine removal UV system in pretreatment, instead of activated carbon filter. At the same time of efficient removal of residual chlorine, system can completely inactivate raw water microorganism, ensuring safety of microorganism from the source and improving quality of supply water. It supports online UV intensity monitoring and dosage display, which can accurately predict dechlorination effect and completely avoid troubles from activated carbon filter. |

|||||

|

Online monitoring of the water quality meets customer needs; The system minimizes the risk of microbial growth, and the dead angle is smaller than the 3D requirement; The drainage adopts the air blocking method to avoid back suction and cross-contamination, and set the lowest point of discharge and a slope of 5‰; The flow rate of the return water in the circulation pipeline is greater than 1m/s to control the growth of microorganisms; The secondary concentrated water, EDI concentrated water, and unqualified purified water are returned to the original water tank for reasonable reuse, saving raw water consumption and reducing later operating costs. |

|

Has three levels of management authority, followed by operator, administrator, and senior administrator. Each login account has a corresponding login password (the password can be modified), and the system will automatically log out after 5 minutes; prevent unauthorized personnel from entering the system from misoperation, and the parameters can be restored to factory settings; Set up overload, high voltage, and low voltage protection in key places of the system, and automatically record all faults and alarm systems; Multi-party internal communication system, at any level of the work site, can view the operating status of each other; When the system fails, the other party will be notified by SMS, and the mobile phone can be realized to observe the operation status. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Packing and shipping

FAQ

Related Products