Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

After the raw water is processed by the multi-effect distilled water machine, the distilled water that has passed the conductivity test can be used as water for injection, and the unqualified distilled water will be automatically discharged.

Distillation is the preferred method for preparing water for injection recognized by all countries in the world. It has a long history and reliable results.

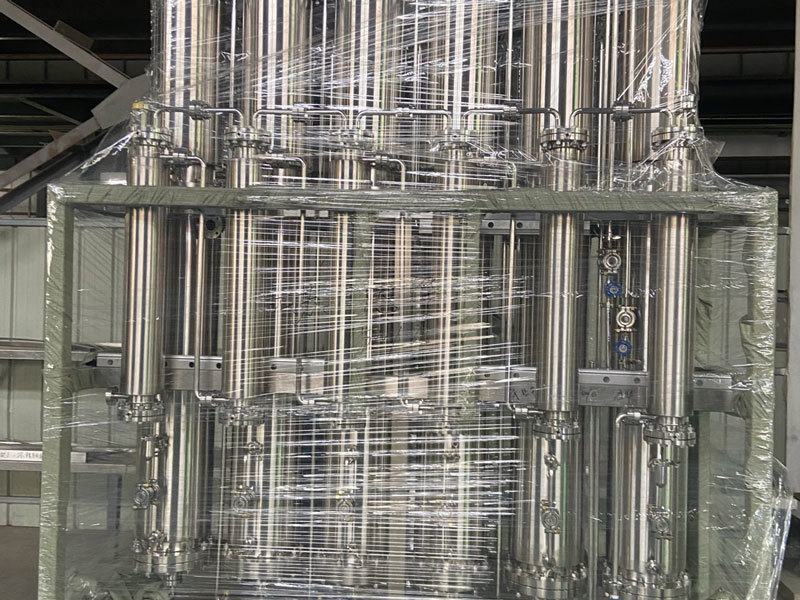

The WFI plant is mainly composed of an evaporator, a preheater, a condenser, and an electrical automatic control part. The evaporator adopts the principle of vertical tube falling film evaporation. In order to ensure the quality of distilled water, a special steam-water separation device is installed in the evaporator.

WFI module also called WFI Pipeline distribution systems should be constructed to allow for the continuous circulation of water in the pipes and to be regularly cleaned and disinfected. A continuously cycling system tends to maintain normal operation.

Water for injection: Purified water is used as raw water, distilled through a specially designed distiller, condensed and cooled, and then prepared by membrane filtration. Water for injection can be used as a solvent for the preparation of injections.

WFI equipment can be obtained by distillation method, reverse osmosis method, ultra-filter method, etc. Various countries have made very clear regulations on the production method of water for injection.

Open the cooling water control valve of the WFI distribution skid, so that the reading of the cooling water pressure gauge reaches 0.2 ~ 0.3MPa (according to the cooling conditions, it can be adjusted to be lower than this number), and at the same time, open the valves of the primary condensate discharge valve and the emptying valve by 45 degrees .

The working principle of tube-type Water distiller for injection, the qualified raw water is pressurized by the multi-stage pump and then enters the condenser for heat exchange, and then enters the preheater of each effect in turn, and then enters the first-effect evaporator and is sprayed in the heating tube by the feed water distributor.

Water distiller has beautiful appearance, reasonable structure, steam saving and water saving, and easy operation, the multi-effect distilled water machine is highly praised by users. It is widely used in hospitals, pharmaceutical factories, chemical research institutes to prepare distilled water. This water distiller for injection is used to produce distilled water for injection, and its water quality complies with the regulations of the Pharmacopoeia of the People's Republic of China on distilled water for injection.

Distilled water production line for injection

Distilled water machine/tube multi-effect distilled water machine/electric high-efficiency distilled water machine/preparation water distilled water machine/cosmetic water distilled water machine/injection water distilled water machine/steam high temperature sterilization/medical equipment water distilled water machine/high temperature pipeline sterilization steam generator/Distilled water production line for injection.

Distilled water injection machine

Basic requirements of tubular distil water production plant(Distilled water injection machine): 1.1 Material/Surface (1) Surfaces that do not come into contact with products and cleaning media: the surface is smooth, easy to clean, and does not react with cleaning agents and disinfectants. Materials are at least 304.

WEMAC provides customers with design, manufacturing,installation and verification support for injection water system and liquid preparation system.

WEMAC LDS series Multi effect water distiller is a kind of water for injection generation equipment using purified water as raw water, and heated by industrial steam.