Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

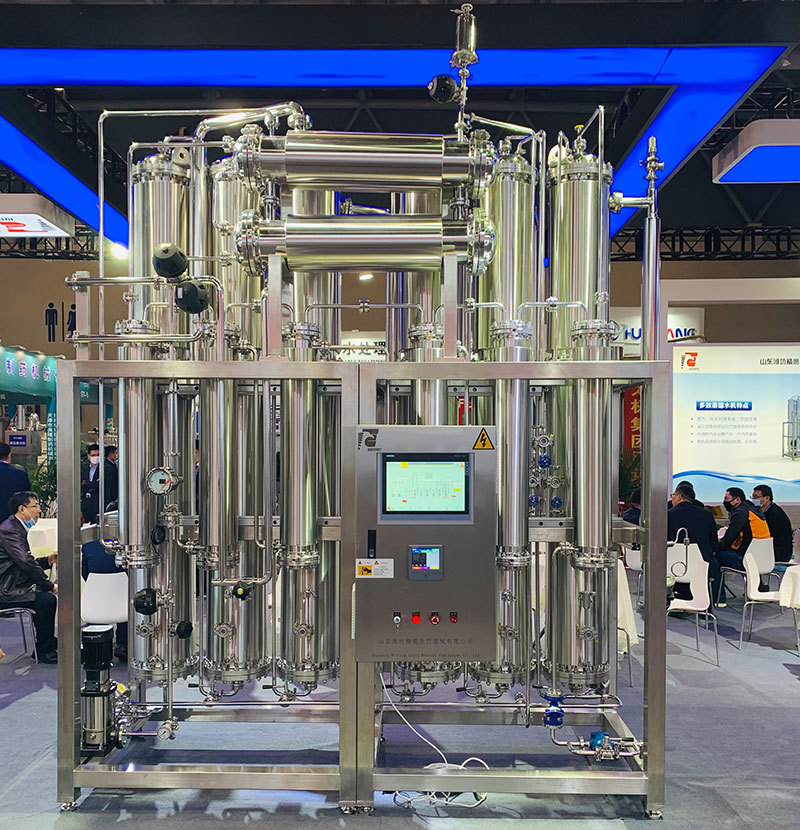

Electric WFI water for injection with independent electric control console. The all-stainless steel electric heater (steam generator) specially developed for this machine adopts automatic control mode for automatic water replenishment, liquid level and steam pressure, which is highly efficient and energy-saving. Integrate with the whole machine.

Distilled water production machine

The distilled water production machine is a distilled water production equipment that uses deionized water as the raw material and is heated by steam. The distilled water produced by distilled water production machine has stable water quality, high purity and no pyrogen, and conforms to the provisions of "Water for Injection" of the 05th edition of "Chinese Pharmacopoeia". Ideal equipment for factories.

After the raw water is processed by the multi-effect distilled water machine, the distilled water that has passed the conductivity test can be used as water for injection, and the unqualified distilled water will be automatically discharged.

Distillation is the preferred method for preparing water for injection recognized by all countries in the world. It has a long history and reliable results.

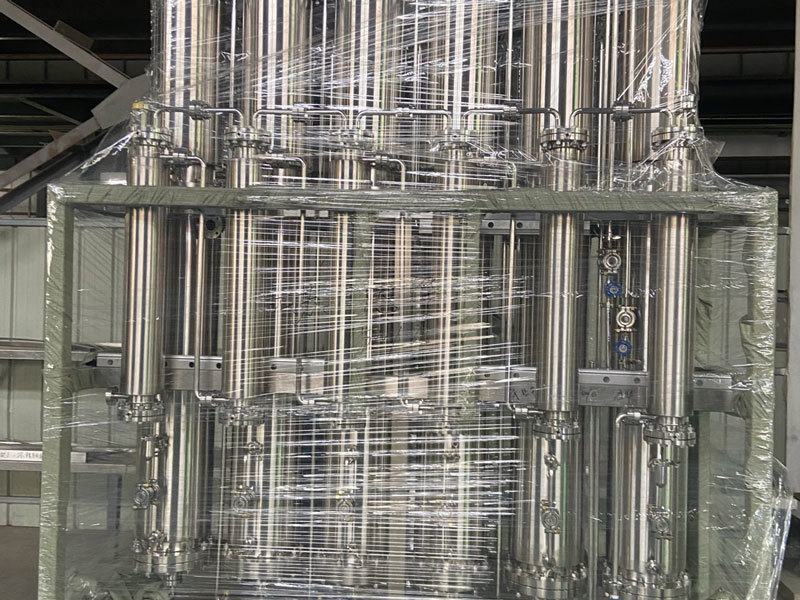

The WFI plant is mainly composed of an evaporator, a preheater, a condenser, and an electrical automatic control part. The evaporator adopts the principle of vertical tube falling film evaporation. In order to ensure the quality of distilled water, a special steam-water separation device is installed in the evaporator.

WFI module also called WFI Pipeline distribution systems should be constructed to allow for the continuous circulation of water in the pipes and to be regularly cleaned and disinfected. A continuously cycling system tends to maintain normal operation.

Water for injection: Purified water is used as raw water, distilled through a specially designed distiller, condensed and cooled, and then prepared by membrane filtration. Water for injection can be used as a solvent for the preparation of injections.

The Water treatment machinery is composed of storage tanks, conveying pumps, conveying circulation pipelines, water points, monitoring and control systems. Temperature and other needs, and maintain water quality in line with pharmacopoeia requirements.

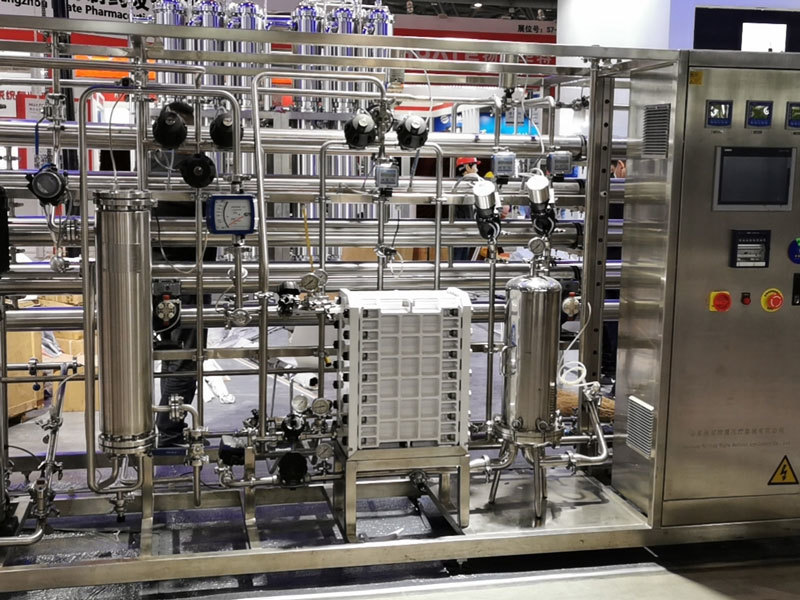

The water treatment process of water system inpharma mainly adopts reverse osmosis technology and is used in conjunction with pretreatment devices, and must be sterilized and sterilized before the water point, and ensure that the produced qualified water can be stably and safely transported to the water point. Reverse osmosis technology is a widely used desalination treatment technology, which can greatly reduce the load of ion resin, and the amount of resin regeneration agent is only 10% of the traditional ion exchange resin process, which not only saves operating costs, but also is relatively friendly to the environment.

Water purifying equipment is a kind of raw material water commonly used in the pharmaceutical industry and participates in the entire production process engineering.

Water purification systems industrial

Pipelines and delivery pumps for transporting purified water and water for injection should be regularly cleaned, disinfected and sterilized, and can only be put into use after passing the verification.

PW water system strictly purifies the raw water to make it meet the water quality standards for pharmaceutical production, and the process from water production to delivery to the water point is easily subject to secondary pollution, which will affect the final water quality effect.

In the process design of pharmaceutical water purification machine, the appropriate process flow is selected according to the user's raw water report and product water standards to ensure that the final product water quality meets the standards.