Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

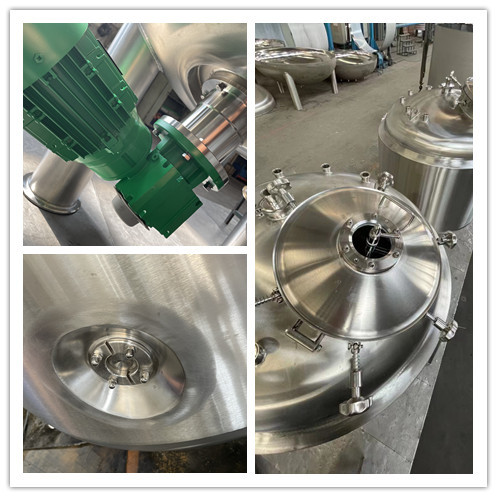

Jacket Manufacturing Tank

WEMAC provides customers with design, manufacturing,installation and verification support for injection water system and liquid preparation system. Design according to the actual needs of the customer’s site and the disinfection requirements, with GMP, ISPE engineering guidelines and FDA specifications as the design concept, rational use of space, convenient use and operation, and selection of high-quality clean pipe fittings. So that the design and installation are free of dead ends and no contamination. The reflux control is reasonable and fully meets the user's requirements and verification requirements.

Keywords:

category:

Details description

WEMAC provides customers with design, manufacturing,installation and verification support for injection water system and liquid preparation system. Design according to the actual needs of the customer’s site and the disinfection requirements, with GMP, ISPE engineering guidelines and FDA specifications as the design concept, rational use of space, convenient use and operation, and selection of high-quality clean pipe fittings. So that the design and installation are free of dead ends and no contamination. The reflux control is reasonable and fully meets the user's requirements and verification requirements.

1.Compact install,attractive layout,and make proper use of the space.

2.Process optimization,convenient operation.

3.Zero dead leg design.

4.Full automatic welding.

5.Endoscopy detection

6.Pressure test and pickling passivation.

The batching tank of the liquid distribution system is divided into top mixing and bottom mixing. This is the Bottom Magnetic Stir Tank.

The body of the tank adopts the double layers structure.

It has the functions of the heating and heat preservation.The interlayer twined helical band is heated by steam or cooled by cooling water.The material of the heat preservation is composite silicate thread felt.

SS316L are used with all the components touching the liquid,SS304 with rest parts.

It is equipped with telescopiform temperature transmitter,sanitary level transmitter,cleaner and vern filter.

We can choose famous Germany brands etc. For electrical reducer,We can also add transducer to realize the steeples speed regulation.

The sealing of the mixer shaft is realized by sanitary double channel mechanical sealing.

Connections adopts ISO2037 clamp fast connections.

It can be customized according to the requirements of customers.

The weighing system can be installed in the batching tank.

| Model | Specification | Reference Size(mm) | |||||

| D | D1 | n-φ3 | H | H1 | H2 | ||

| PG100 | 100 | 600 | 700 | Φ200 | 1898 | 380 | 300 |

| PG200 | 200 | 800 | 900 | Φ250 | 1939 | 350 | 374 |

| PG300 | 300 | 800 | 900 | Φ250 | 2039 | 450 | 474 |

| PG500 | 500 | 900 | 1000 | Φ300 | 2270 | 640 | 664 |

| PG600 | 600 | 900 | 1000 | Φ300 | 2419 | 830 | 853 |

| PG800 | 800 | 1000 | 1100 | Φ350 | 2659 | 890 | 913 |

| PG1000 | 1000 | 1100 | 1200 | Φ350 | 2710 | 900 | 920 |

| PG1500 | 1500 | 1300 | 1400 | Φ400 | 2848 | 960 | 984 |

| PG2000 | 2000 | 1400 | 1500 | 2-Φ400 | 3027 | 1100 | 1120 |

| PG2500 | 2500 | 1500 | 1600 | 2-Φ450 | 3169 | 1200 | 1220 |

| PG3000 | 3000 | 1600 | 1700 | 2-Φ500 | 3308 | 1300 | 1325 |

| PG4000 | 4000 | 1900 | 2000 | 2-Φ500 | 3273 | 1150 | 1174 |

| PG5000 | 5000 | 1900 | 2000 | 2-Φ600 | 3623 | 1500 | 1524 |

| PG6000 | 6000 | 2100 | 2200 | 2-Φ600 | 3657 | 1430 | 1456 |

|

|

|

|

|

|

|

|

Packing and shipping

FAQ

Related Products