Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

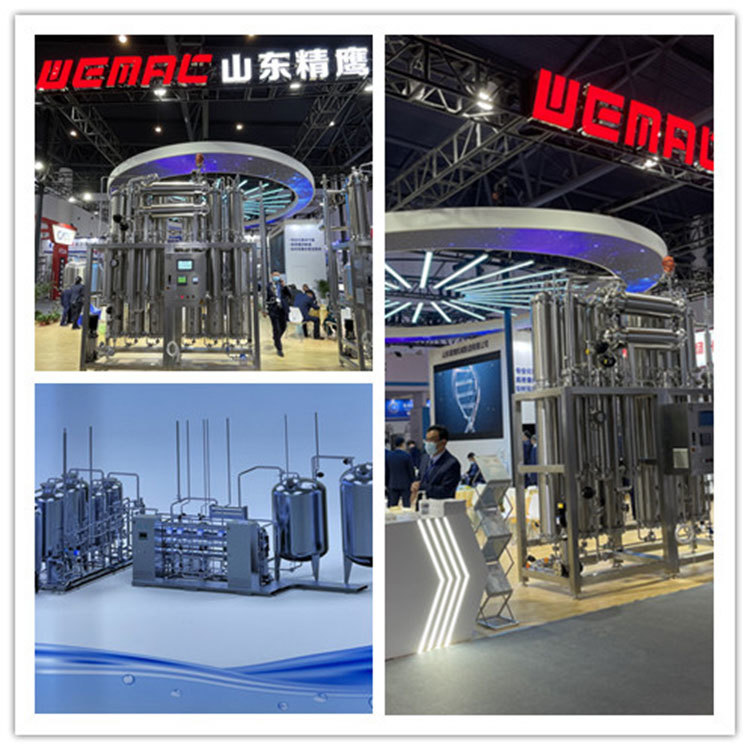

Multi effect water distiller

WEMAC customized optimization design according to the raw water quality report,effluent quality requirements and the actual needs of customers, and customer can also choose the standardized design from WEMAC. The output water quality can meet the requirements of Chinese Pharmacopoeia(CP2020), United States Pharmacopoeia (USP43) and European Pharmacopoeia (EP10) for purified water or high purity water according to different system configurations.

Keywords:

category:

Details description

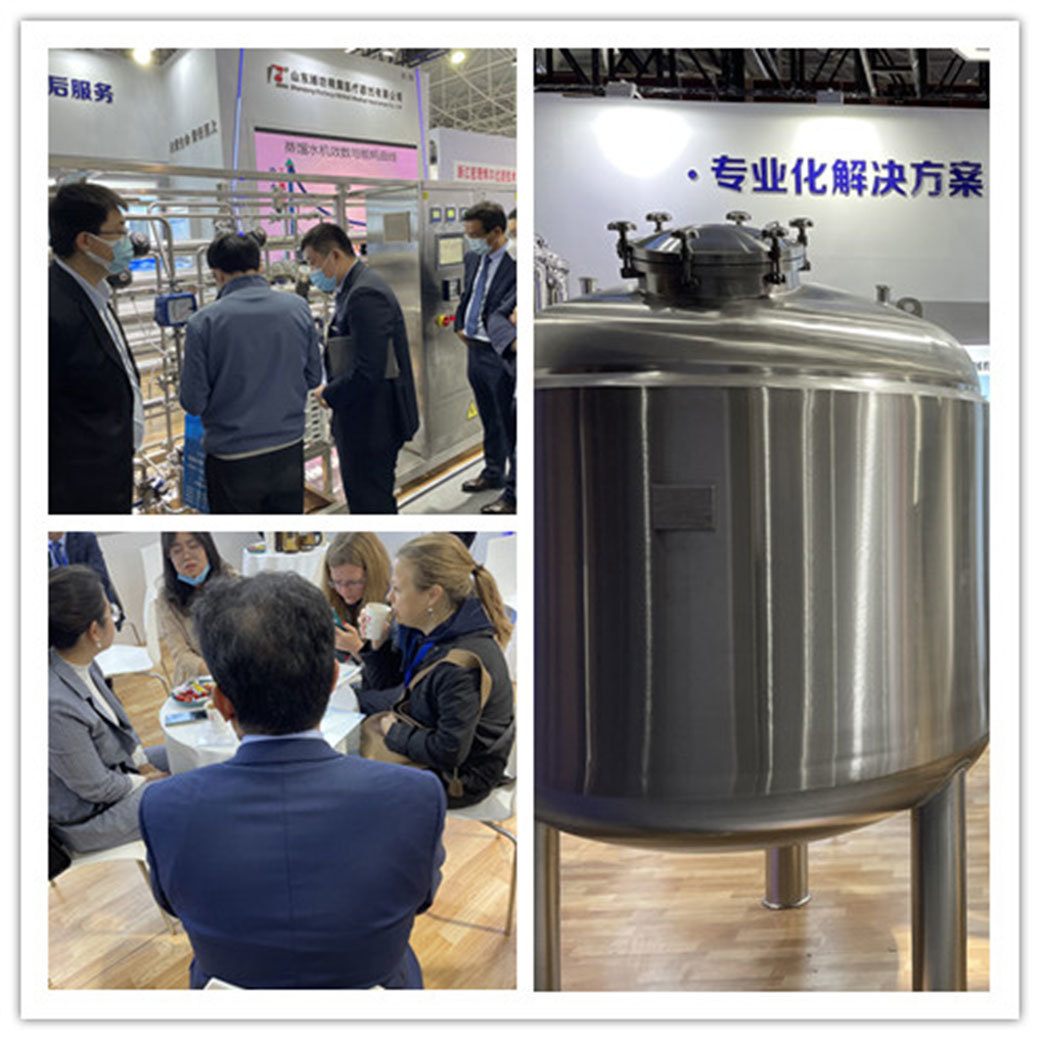

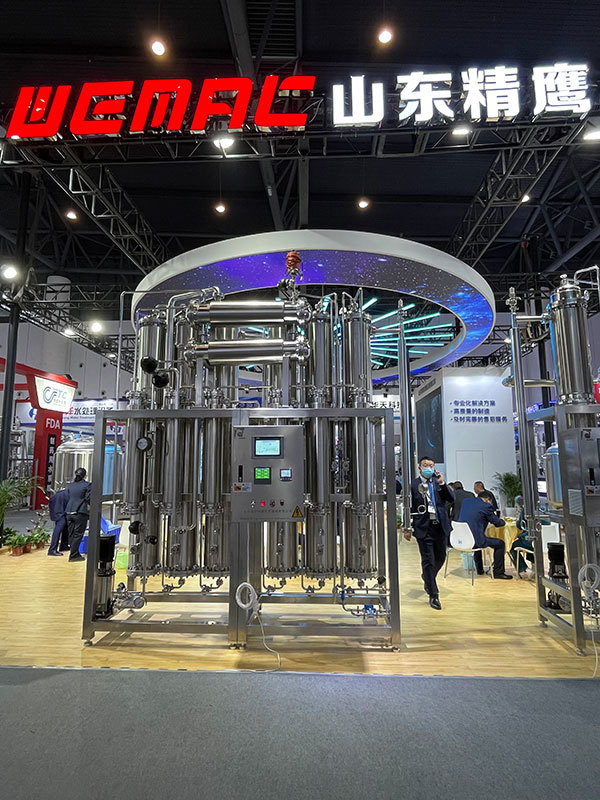

The multi-effect water distiller is the key equipment of the widely used water injection preparation system. The multi-effect water distiller adopts high temperature and high pressure operation to ensure stable production of pyrogen-free water for injection. WEMAC customized optimization design according to the raw water quality report,effluent quality requirements and the actual needs of customers, and customer can also choose the standardized design from WEMAC. The output water quality can meet the requirements of Chinese Pharmacopoeia(CP2020), United States Pharmacopoeia (USP43) and European Pharmacopoeia (EP10) for purified water or high purity water according to different system configurations.

1.Structural material: pressure vessel body and pipes in contact with distilled water and secondary pure steam are made of 316L, and the sealing material is made of PTFE. Other materials include the use of 304 material for the frame.

2.Modular design, compact structure, beautiful layout, convenient operation and maintenance.

3. The double softeners in pretreatment unit can realize series operation and alternate regeneration by using valve group. Each water softener has 100% water supply capacity. The whole process of softener operation, backwashing, salt absorption, regeneration and washing is fully automatic and programmed.

4..Frequency conversion control is adopted for raw water pump, RO1 and RO2 high-pressure pumps, which can not only realize different pressure control of filter and softener under various operating conditions, but also realize low-speed and small circulation of produced water in system standby time, greatly reducing the probability of microbial breeding and effectively saving energy.

5. The terminal water production of the system adopts a dual-channel water supply and single-channel circulation mode, that is, when the product water is qualified, it enters the purified water storage tank through two pipelines. While when the product water is unqualified, the product water circulates through the two pipelines and then flows back to the middle water storage tank. When the purified water storage tank is full, it will automatically switch to the circulation pipeline operation, which effectively avoids the existence of empty pipes and ensures that there is no dead water.

6. The middle water storage tank is used as the buffer tank to realize online cleaning, eliminating the separate cleaning system. The system can choose thermal disinfection RO membrane and thermal disinfection EDI to realize online hot water sanitization of the whole system.

7. As far as possible, use stainless steel pipes to directly stretch the elbow to avoid welding seam. Welding parts of pipelines and accessories should be automatically welded with argon protection(single-side welding and double-side forming process) to ensure welding quality, and electrochemical polishing after welding.

8. Provide endoscopy photos, solder joint diagram, pressure test and pickling passivation report, system design documents and other verification data.

9. The control system adopts HMI+PLC fully automatic control, and the operation interface is simple. Various communication modes are available. Control system authority levels: at least three levels of authority can be set.

10. Online monitoring of parameters such as conductivity, temperature and flow. The recorder can choose a paperless recorder or a paper recorder to record and print key parameters.

11. The control system can be optionally equipped with electronic signatures and electronic records, so that the system control has an audit trail function, and meets the requirements of GAMP 5 and 21 CFR PART

12.Recording mode:You can choose the paperless recorder,and also paper recorder to record the key parameters in real time.

13.The whole machine performance factory test: in the whole machine test workshop, according to the determined procedure, simulate the actual working environment, carry out the whole machine test.

Can choose 304 or 316L material, and use professional equipment and equipment to strictly inspect the quality;

Modular 3D design, construction according to drawings;

The pipeline connection method uses welding first, followed by clamp connection to control the growth of microorganisms;

Using orbital automatic welding machine, 20% endoscope inspection after welding, 100% endoscope inspection after manual welding;

Online conductivity monitoring, qualified distilled water becomes water for injection;

The system minimizes the risk of microbial growth, and the dead angle is smaller than the 3D requirement;

The drainage adopts the air blocking method to avoid back suction and cross-contamination, and set the lowest point of discharge and a slope of 5‰;

The flow rate of the return water in the circulation pipeline is greater than 1m/s to control the growth of microorganisms;

Superb welding technology

A pharmaceutical water plant with more than 60 years of operation

Keep improving every detail

| Model | Capacity | Industry steam consumption(L/h) | Feed water consumption(L/h) | Cooling water consumption(L/h) | Dimensions(mm) |

| LDS100-4 | ≥100 | 30 | 110 | 80 | 1065*540*1900 |

| LDS300-5 | ≥300 | 80 | 330 | 170 | 1610*650*2300 |

| LDS500-4 | ≥500 | 150 | 550 | 550 | 1540*770*3150 |

| LDS500-5 | ≥1000 | 115 | 550 | 190 | 1900*770*3150 |

| LDS1000-5 | ≥1000 | 250 | 1100 | 350 | 2200*1000*3400 |

| LDS1000-6 | ≥2000 | 210 | 1100 | 0 | 2830*1000*3400 |

| LDS2000-5 | ≥2000 | 520 | 2200 | 750 | 3000*1200*3600 |

| LDS2000-6 | ≥2000 | 440 | 2200 | 0 | 3510*1200*3600 |

| LDS3000-6 | ≥3000 | 670 | 3300 | 0 | 3600*1200*3750 |

| LDS4000-6 | ≥4000 | 900 | 4400 | 0 | 4080*1250*4000 |

| LDS5000-6 | ≥5000 | 1130 | 5500 | 0 | 4470*1450*4250 |

| LDS6000-6 | ≥6000 | 1350 | 6600 | 0 | 4470*1450*4500 |

|

|

|

|

|

|

|

|

|

|

|

|

Packing and shipping

FAQ

Related Products