Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

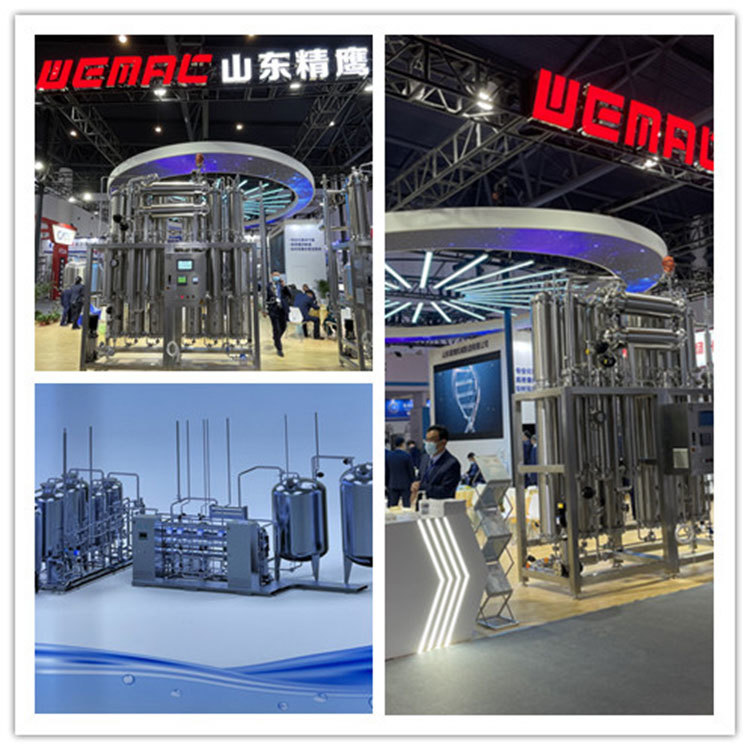

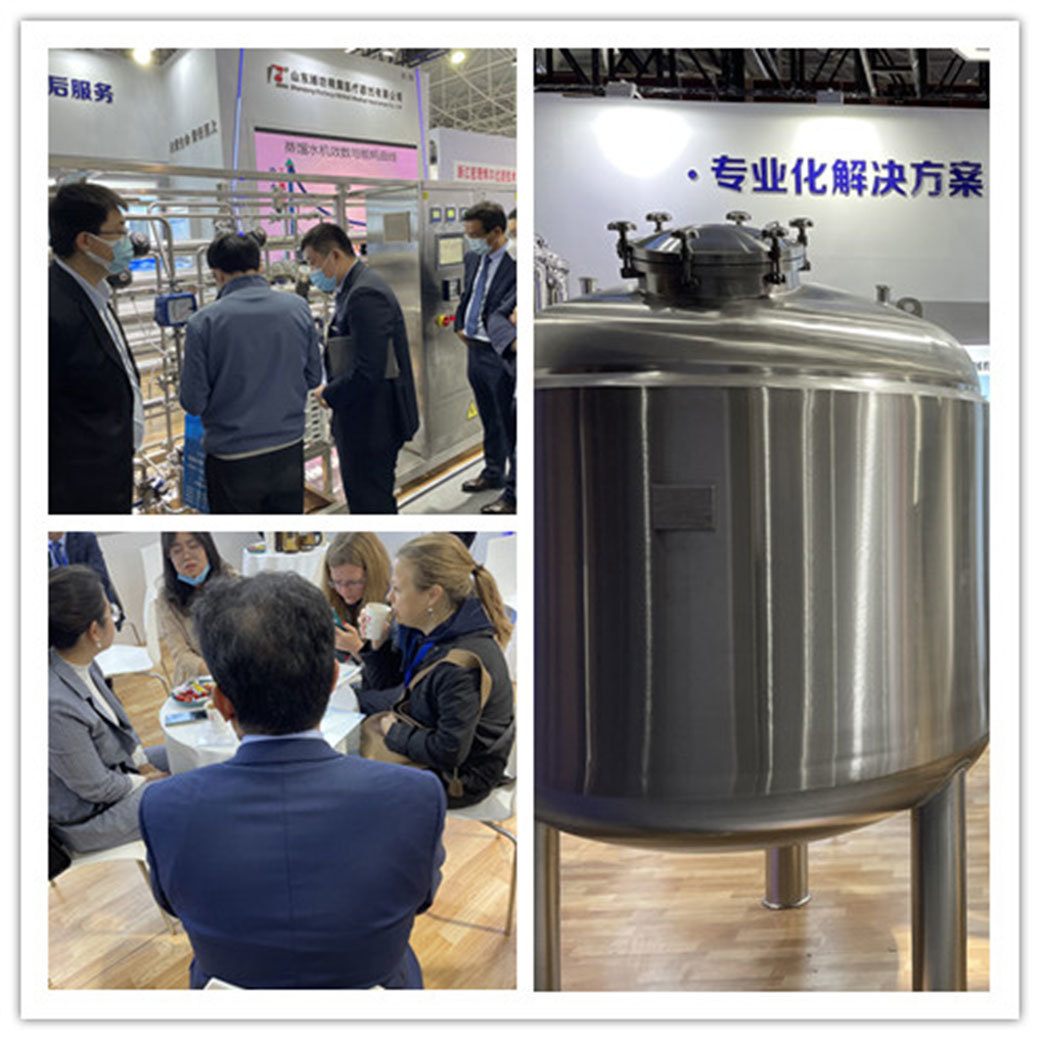

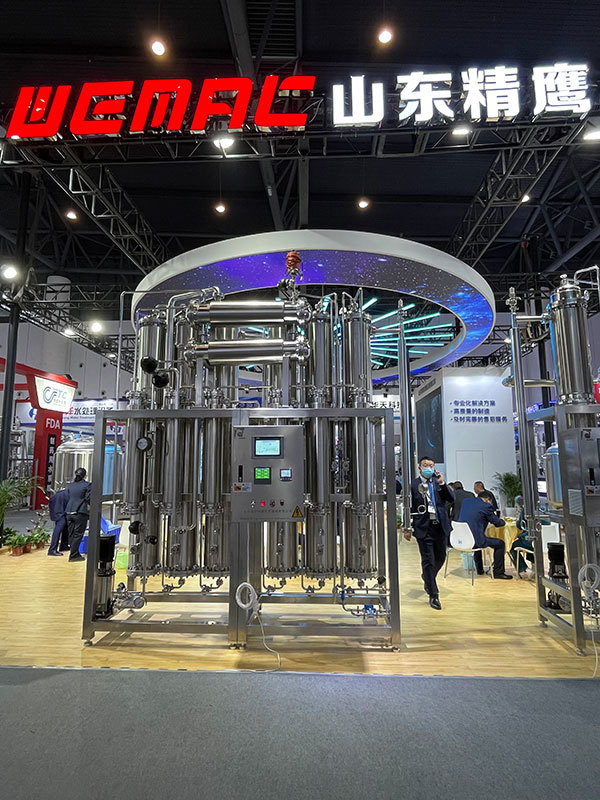

Five effect water distiller

The multi-effect water distiller is the key equipment of the widely used water injection preparation system. The multi-effect water distiller adopts high temperature and high pressure operation to ensure stable production of pyrogen-free water for injection.

Keywords:

category:

Details description

Technical features of five effect water distiller:

1. All materials in contact with distilled water and pure steam are 316L, and the sealing material is PTFE.

2. Three-stage separation, double tube sheet design, can effectively avoid cross-contamination, electrochemical polishing, and ensure the quality of water for injection.

3. The pipeline of the whole machine adopts automatic welding, and the tubes are made of well-known brand seamless tubes to ensure that they remain in good condition during welding, expansion and thermal expansion and contraction during operation, and to ensure the possibility of cross-contamination.

4. Structural material: The pressure vessel body and pipeline in contact with distilled water and secondary pure steam are 316L, and the sealing material is PTFE. Other materials including the frame are made of 304 material.

5. Three-stage separation device: The raw water entering the equipment is separated by three stages of falling liquid film evaporation, gravity separation and special separation device.

6. Electrochemical polishing: The stainless steel surface is electrochemically polished to ensure the quality of water for injection production and improve the service life of the equipment.

7. Double tube plate design: The external preheater, condenser and first-effect evaporator are all designed with double tube plates, which meet the requirements of cGMP and effectively eliminate the possibility of low sanitation level media contamination of the system.

8. High-quality seamless tubes are used for heat exchange tubes: seamless tubes have better strength and durability, ensuring that they remain in good condition during processing, welding, expansion, and thermal expansion and contraction during operation, ensuring that any industrial steam is avoided. , raw material water and cooling water leak into clean distilled water and secondary steam side.

9. Three-dimensional elbow: Use stainless steel pipe to directly stretch the elbow on the pipeline as much as possible to avoid welding.

10. Use automatic welding: For the connection between pipelines and parts, use automatic argon shielded track welding as much as possible to ensure welding quality.

11. Insulation: Both the evaporator and the preheater are made of chlorine-free and asbestos-free mineral wool insulation, and are covered with stainless steel cladding.

12. Only economical pretreatment of feed water is required: no expensive purified water equipment is required, and only deionized water or reverse osmosis water with conductivity less than 5μS/cm is required for feed water.

13. Economical and energy-saving: The multi-effect distilled water machine has a high utilization rate of industrial steam due to the use of secondary steam in each effect step by step, and has obvious energy-saving effect. With the increase of evaporator efficiency, the effect of this energy saving is more obvious. At the same time, the amount of cooling water is also greatly reduced with the increase of the effect number.

14. Control system: PLC automatic control technology is adopted to realize different control requirements of customers. From the most basic judgment and distribution of distilled water quality, to more advanced ones such as continuous adjustment of various media, linkage with storage systems, hierarchical password control and even control of evaporation changes, it can be said to be meticulous.

15. Paperless record: The paperless record method is adopted to record the actual production situation.

16. Factory test of the whole machine performance: In the whole machine test workshop, according to the determined procedure, simulate the actual working environment, and conduct the whole machine test.

| Model | Capacity | Industry steam consumption(L/h) | Feed water consumption(L/h) | Cooling water consumption(L/h) | Dimensions(mm) |

| LDS100-4 | ≥100 | 30 | 110 | 80 | 1065*540*1900 |

| LDS300-5 | ≥300 | 80 | 330 | 170 | 1610*650*2300 |

| LDS500-4 | ≥500 | 150 | 550 | 550 | 1540*770*3150 |

| LDS500-5 | ≥1000 | 115 | 550 | 190 | 1900*770*3150 |

| LDS1000-5 | ≥1000 | 250 | 1100 | 350 | 2200*1000*3400 |

| LDS1000-6 | ≥2000 | 210 | 1100 | 0 | 2830*1000*3400 |

| LDS2000-5 | ≥2000 | 520 | 2200 | 750 | 3000*1200*3600 |

| LDS2000-6 | ≥2000 | 440 | 2200 | 0 | 3510*1200*3600 |

| LDS3000-6 | ≥3000 | 670 | 3300 | 0 | 3600*1200*3750 |

| LDS4000-6 | ≥4000 | 900 | 4400 | 0 | 4080*1250*4000 |

| LDS5000-6 | ≥5000 | 1130 | 5500 | 0 | 4470*1450*4250 |

| LDS6000-6 | ≥6000 | 1350 | 6600 | 0 | 4470*1450*4500 |

|

|

|

|

|

|

|

|

|

|

|

|

Packing and shipping

FAQ

Related Products