Welcome to the official website of Shandong Eagle Pharma Machinery Co.,Ltd.!

Service Hotline:+86-536-8800237

Product Center

Contact Us

Address: Block B, Headquarters Base ABP, No.2600, Zhuangjian Road.Weifang, Shandong, P.R.C.

Tel: +86-536-8800237

Email: export@sdwemac.com

WhatsApp: Naomi: 86 15315252862

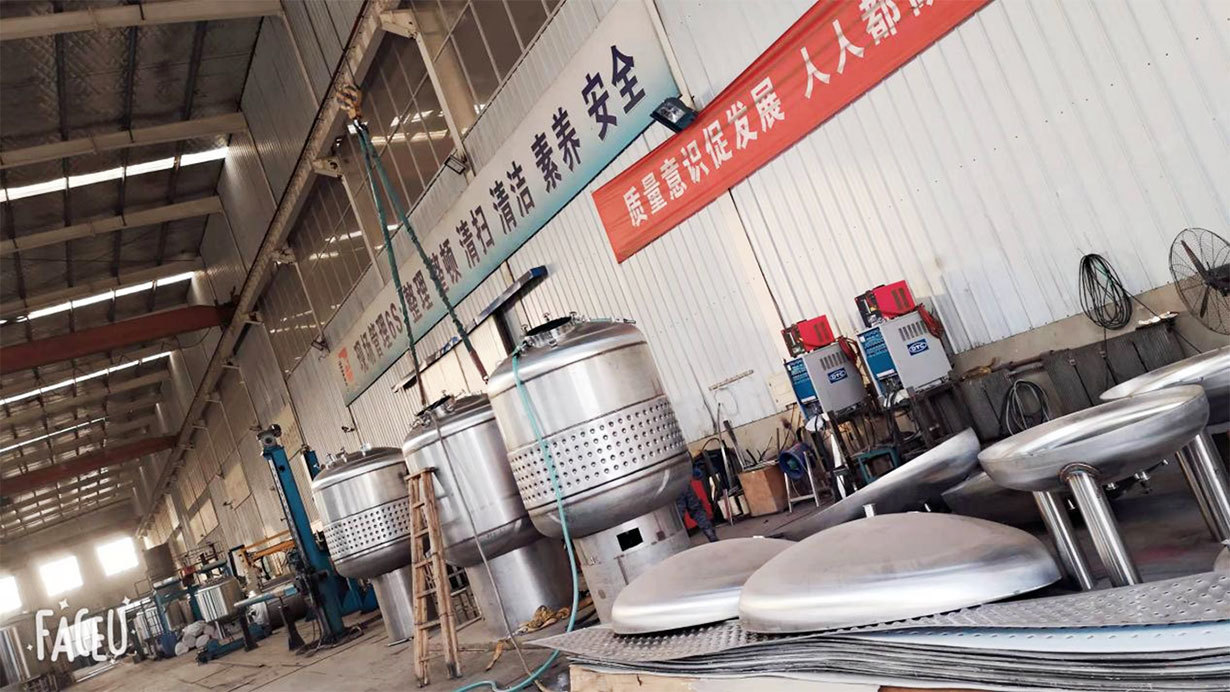

Vertical WFI tank

With heating and heat preservation functions. The spiral belt wound in the interlayer is heated by steam or cooled by cold water. And the insulation material is made of glass fiber needled felt.

Keywords:

category:

Details description

With heating and heat preservation functions. The spiral belt wound in the interlayer is heated by steam or cooled by cold water. And the insulation material is made of glass fiber needled felt. Equipped with temperature sensor, sanitary level sensor, spray ball and vent filter;

the internal tank is made of SS316L or SS304, the internal surface is mirror polished Ra0.4, and the external surface is matted; it can be individually designed and processed according to customer requirements.

(1) Purified water and distilled water storage tanks are manufactured in full accordance with the requirements of national GMP certification regulations.

(2) Automatic control to ensure the process requirements of 80°C memory, 65°C small cycle and large cycle.

(3) The tanks are of vertical or horizontal type, both of which are single-layer and double-layer structures.

(4) The polishing accuracy of the inner tank is less than RaO.4, the polishing accuracy of the outer tank is less than Ra0.8, and the inner tank is made of 316L or 304.

(5) The inner cylinder is heated with a spiral belt and filled with glass fiber needle felt for heat preservation.

(6) Mirror panels or frosted boards are used for heat preservation on the outside, and the tank body has the same luster. ...

(7) All parts that contact the liquid chemical are made of 316L, and the rest are made of 304.

(8) There are water inlets, return ports, disinfection ports, cleaning ports, manholes, and 0.22um electric heating air filters on the top. The bottom is equipped with a zero dead angle tank bottom diaphragm valve, a condensate outlet, a distilled water outlet, a sewage outlet, a liquid level measurement port, and a temperature measurement port.

(9) The jacket part and cylinder are equipped with safety valves and pressure gauges, which can be monitored in real time.

(10) Equipped with a control cabinet for operation, and the meter displays the temperature and liquid level of distilled water.

(11) Realize automatic temperature control and provide functions such as upper and lower limit alarms.

(12) Equipped with temperature sensor, sanitary level sensor, washer, and air breathing apparatus.

(13) It can be individually designed and processed according to customer requirements

| Model | Specification | Reference Size(mm) | ||||||

| D | D1 | H | H1 | H2 | H3 | H4 | ||

| CHL300 | 300 | 800 | 900 | 1484 | 460 | 461 | 820 | 400 |

| CHL500 | 500 | 900 | 1000 | 1587 | 530 | 530 | 928 | 400 |

| CHL1000 | 1000 | 1100 | 1200 | 1878 | 750 | 750 | 1356 | 400 |

| CHL2000 | 2000 | 1300 | 1400 | 2463 | 1220 | 1220 | 1926 | 400 |

| CHL3000 | 3000 | 1600 | 1700 | 2395 | 1220 | 1100 | 2070 | 400 |

| CHL4000 | 4000 | 1800 | 1900 | 2557 | 1220 | 1220 | 2220 | 400 |

| CHL5000 | 5000 | 1900 | 2000 | 2637 | 1220 | 1220 | 2220 | 400 |

| CHL6000 | 6000 | 2000 | 2100 | 2806 | 1380 | 1380 | 2206 | 400 |

| CHL8000 | 8000 | 2200 | 2300 | 3226 | 1500 | 1500 | 2680 | 400 |

| CHL10000 | 10000 | 2400 | 2500 | 3450 | 1580 | 1780 | 2780 | 400 |

|

|

|

|

|

|

|

Packing and shipping

FAQ

Related Products